With the advancements in CAD/CAM and CNC machinery over the years a new breed of watches is born. They are the Clone watches that are being offered only by Swisstime.sr online and contain genuine swiss made parts and top shelf swiss made clone movements the same found in genuine watches. We are the only Clone watch manufacturer who uses Genuine Swiss Made Parts to create the whole watch. Then the assembly is made in Switzerland by experienced certified master watchmakers with over 20 years experience working on Swiss watches.

Our Clones weight and feel exactly the same as to an Original watch. Our watches may be Clones but when you purchase a Swiss timepiece through our company you are paying for the Swiss made level of quality and craftsmanship. Considering what you are purchasing in terms of an overall watch, comparable timepieces retain for thousands of dollars more. The movement found in our products is a Swiss clone of the same caliber used in high end Swiss watches such as Rolex, AP, Hublot, Panerai etc. The bottom line is you are getting a quality timepiece to last a lifetime and on top of that it looks and feels just like the real Genuine watch.

Our Swiss jewellers have constructed the perfect Clone and these watches are made 1:1. A genuine watch was used as a sample and was completely disassembled for cloning so all parts are interchangeable with genuine. This is achieved by having the genuine watch completely disassembled and then all parts cloned by using the most advanced CAD/CAM, modular molds and CNC Laser Machines. Our watches are Swiss timepieces with Swiss level of quality and craftsmanship. The most accurate Swiss Made Clones in the world.

〰

904L Stainless Steel

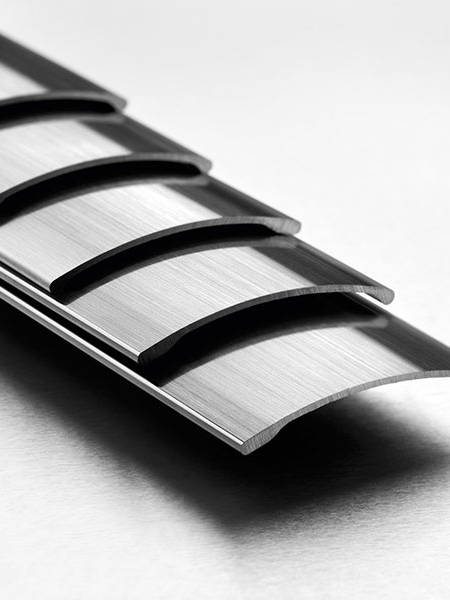

Every watch case is made from the highest quality 904L stainless steel provided by the leader in the steel industry, Allegheny Ludlum. 904L extends an outstanding overall corrosion and sensitization resistant properties which makes it the most suitable choice to provide the best quality casing. We use the most advanced version of CAD/CAM and Laser CNC machines to create all our watch parts.

The Rolex cases include the serial and model number on the lugs which corresponds to new production. From no pinholes on the watch cases to thicker hand on the Yachtmaster our watches are simply heads and shoulders above the competition. Our bands linked by threaded screws. Genuine Rolex bracelets are linked together by threaded screws. All other replica Rolex watches has a pin instead of a screw. It is much more expensive to thread the interior of a link and even more expensive for the jeweller to manually insert the screw. The links are also much easier to adjust.

Whatever markings, engravings or features a genuine watch have, you will also find on our Clone. These are quality Swiss timepieces so you can be sure that every last detail is inspected before these watches leave the manufacturer.

〰

Grade 5 Titanium

We use only Titanium Grade 5 which is has a high corrosion resistance and extremely high strength to weight ratio. Most watches are manufactured with stainless steel, but an increasing number of timepieces feature titanium cases. The popularity of titanium watches has increased since about 2000 because it’s a lightweight metal about 50 percent lighter than stainless steel and is resistant to corrosion. Sports-style watches marketed for wear in the water are often made of titanium.

Titanium is about 30 percent stronger than steel but weighs about half as much. It’s a silver-grey material that is excavated from sand deposits and igneous rocks. Titanium is primarily used in NASA space and aircraft construction. The qualities of titanium include an oxide film that can’t corrode or rust.

The obvious distinction between titanium and stainless steel is that stainless-steel-cased watches are heavier than titanium. This is not necessarily a drawback since watch styles in the first decade of the 21st century have evolved to larger and heavier timepieces to give what watch enthusiasts call “wrist presence.” Although Titanium watches are more durable, it’s possible they can crack under extreme abuse or pressure. Titanium watch cases can’t be repaired. Stainless steel cases can be. Titanium is hypoallergenic. Stainless steel can be uncomfortable to wear if the skin perspires.

〰

Solid High-Tech Ceramic

An ideal watchmaking material, ceramic is 30% lighter than steel, 100% anti-allergenic, 100% unalterable and 100% rust-proof. Its light weight, scratch resistance, durable and smooth touch. Cerasuisse SA Geneva developed Isocera a special high-teach ceramic compound exclusive for Swisstime.sr. Our Ceramic sandwich bezels and Ceramic cases are solid ISOCERA wich is 2 times harder compared to Rolex Ceracrhom ceramic.

Isocera is zirconium oxide ceramic and it is moulded from powder using a process of isostatic pressure (instead of being cast as is the normal practice). In this way all the positive features of this material are enhanced: its extreme hardness (up to five times greater than steel), its strong resistance to a wide range of temperatures, and the fact that when worn for long periods the watch does not become scratched, damaged or corroded. Also, ceramic formed in this way takes on a more homogenous appearance than that resulting from the traditional method of casting the material.

〰

Real 18K Gold Heavy Wrap

Our 2-tone watches have real 18K heavy wrap gold parts, on the middle link, crown and bezel. The all gold watches now come in heavy wrap 18K Gold. That is twice the gold content found even on the genuine Swiss gold wrapped watches. This results in a watch that tests positive for 18K gold (since the layer is 7 times thicker than simple gold wrap) with Titanium Nitride layers in base and real 18k Gold layers on top. The watch therefore looks and feels just like the real thing. It can even be polished without fade. This method saves thousands of dollars, because you are only paying for a layer of 18K gold instead for the whole weight of the band and case.

Heavy Gold Wrap Solid 18k Gold & Titanium Nitride (TiN)

Now featuring on all our “full” gold models is a revolutionary gold technique using solid 18k gold and titanium nitride offers 100x more durability in comparison to gold wrapped. Space age gold colored titanium nitride is put down first as a “rough” deposit and then layer upon layer of solid 18k gold is fused into the valleys of the rough surface. The same solid gold content is used as in previous techniques but it is now protected by the “peaks” of color matched TiN, so it doesn’t wear away.

This method although more expensive to produce, provides for an incredibly long lasting perfect appearance, which could not be equaled by any other gold plating method. You wont find this improved gold method on other sites, this is exclusively contracted to Swisstime for our unique all gold collection. Titanium Nitride (TiN) is also used as a non-toxic exterior for medical implants.

〰

DLC Coating

Physical Vapor Deposition (PVD) is the method used to deposit thin layers of material by condensation of vapor in a high temperature and vacuum environment. DLC or Diamond-like carbon coating is the highest quality in black coating, the most durable and hardest to scratch. The coating is done with the bonding of high energy precursive carbon rapidly cooled down on the surface. It is very similar to the process of making synthetic diamonds. Not only the process is similar but the carbon coatings have the same attributes as diamonds since they are extremely hard and very resistant to scratches. In other words it is perfect for making metal surfaces more durable.

The DLC is way more resistant than any other material, perhaps a little more expensive but it is worth it. Here at Swisstime we only use DLC to customize our Rolex, Panerai, Audemars Piguet and Hublot Watches since we want to use the highest quality in our products. Diamond Like Carbon coating has many commercial applications, including machine tools, aerospace parts, F1 engine parts, pharmaceutical implants, and of course, high end watches.

There are a few key characteristic of DLC, which has helped it to supplant the use of PVD as a cosmetic coating for fine timepieces:

IT’S HARDER

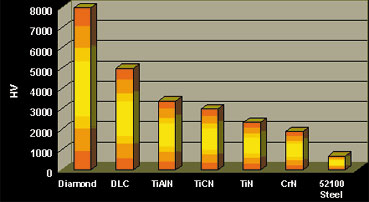

DLC is an extremely hard coating. The following shows the comparative surface hardness of various materials, using the Vickers of Hardness scale:

DLC Hardness Chart

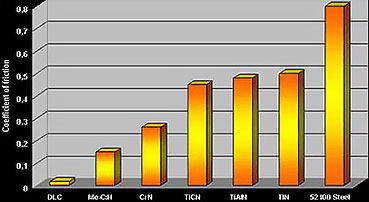

DLC Coefficient Of Friction Chart

In terms of relative hardness, DLC, at 4000+ HV is:

– About 5X as hard as stainless steel

– About equal to sapphire

– About one-half as hard as diamond

– Significantly harder than other PVD coatings

IT’S EXTREMELY WEAR RESISTANT

Because of its durability, DLC is used as tribological coating for machine tools such as drill bits, saws, and dies. When used on a watch, DLC coatings provide superior durability and wear resistance.

IT HAS A LOWER COEFFICIENT OF FRICTION

DLC is quite slick. The following chart compares the coefficient of friction of DLC and other materials:

One of the primary uses of DLC is as a dry lubricant for pumps, machine parts, bearings, cams…even razor blades. The low-friction attributes of DLC help to increase the durability of the coating when used on watches. Glancing blows against a hard surface, which may dig in and damage normal PVD coating, are more likely to simply slide over across the surface of a DLC coated case. Simply stated, it’s just more difficult to damage a DLC coating. These characteristics, along with the beauty of DLC, have helped it to grow in popularity as a hard surface coating for fine watches.